By Jason S. Darley

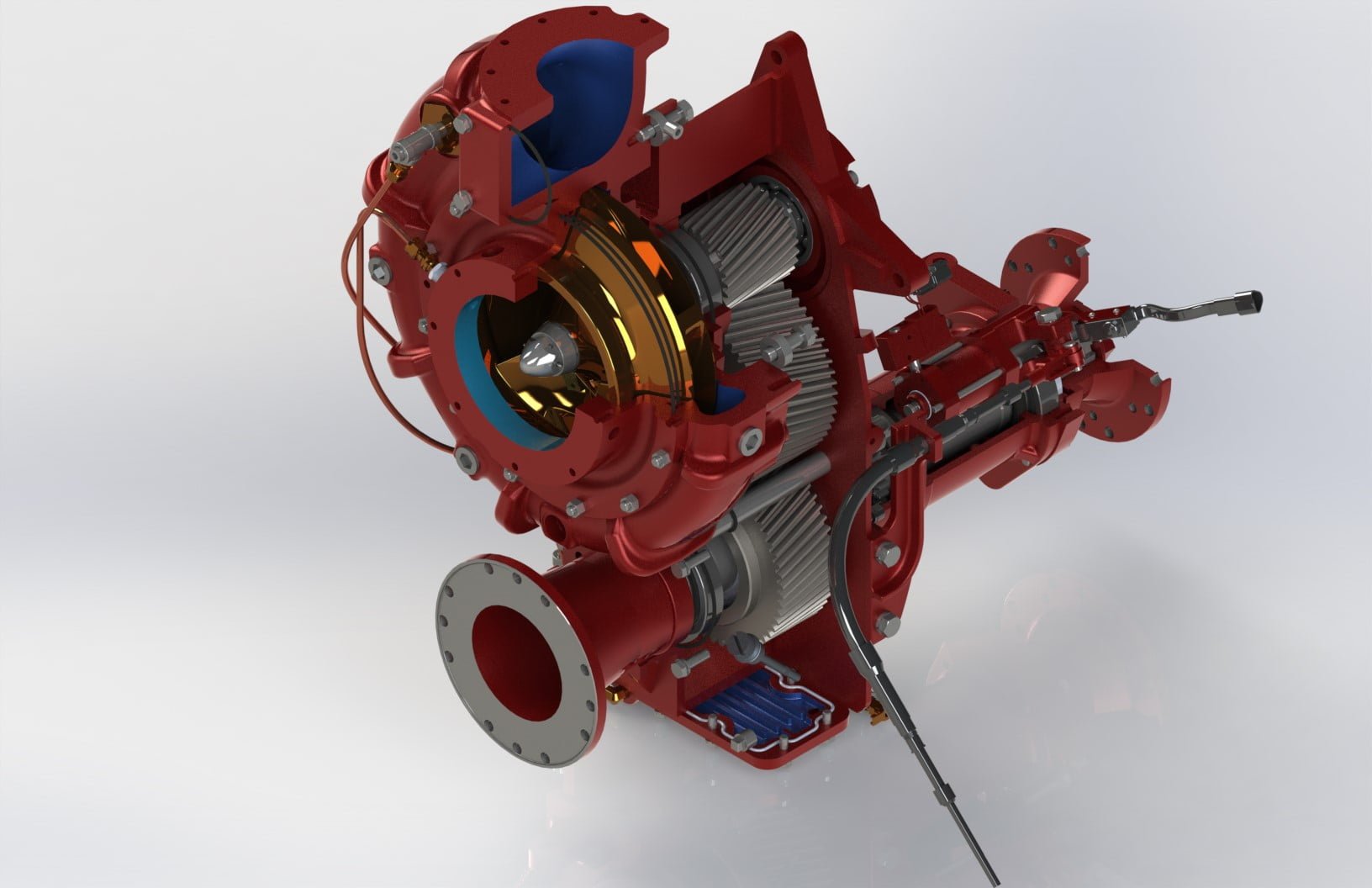

In 2021, Darley celebrated the first shipments of our new TSM product, originally released to the OEM market in spring 2020. Not only does this product fill a long-empty gap in our product mix in a single-suction 2,000-gallons-per-minute (gpm) product, but we learned from our product vetting process that the TSM is a capable answer to a market need.

We worked with several OEMs on validation testing in different applications featuring different plumbing configurations, engine sizes, and pump house configurations. Through the process the results were positive. The overwhelming response was that the TSM 2000 is a strong performer, featuring many of the same components that Darley’s customer base has come to expect. Those elements include vibration-free performance, quieter-than-average operations through the National Fire Protection Association (NFPA) pump test points, and strong reserve capacity. There was, however, one specific thing we found that was a bit unexpected.

A 2,000-gpm pump is required by NFPA to meet specific pressures and flow rates at performances from 100% down to 50% of the rated flow, just like all rated pumps. Outside of those numbers, the unexpected and continual feedback we heard during the process had nothing to do with operations at the “normal” NFPA test points. The challenge the market was looking for Darley to solve was based on consistent feedback from fire departments around the globe who we jointly serve.

Related: Darley 1.5AGE24K a Wildland Workhorse

The challenge? Reducing the higher than normally expected noise from larger pumps at low flows and pressures, like those that would be consistent with operating a single hand line, during mop up, or small fires. In the mechanical or manufacturing world, one would typically associate noise with increased performance. In a race car, for example, the decibel levels are likely to be loudest when the driver is “standing” on the gas pedal. The challenge here defied that logic.

There are several potential source areas of harmonic frequencies and noise in a fire pump. Darley’s engineering team went to work. The results were not immediate and the work unfortunately not something that came in a “lightbulb moment” of any sort, but through significant time modeling, theorizing, and running the TSM product in varying states with subtle tweaks in the test rooms at Darley.

The source? The solution? Perhaps a bit like a certain colonel from Kentucky’s secret recipe which cannot be published here, but the results are in, and the testing confirmed and validated. The TSM 2000 is not only a smooth and quiet performer at normal NFPA test points, but throughout the full range of the performance curve from single low hand line flow performance through the NFPA overflow test point of 2,000-gpm at 165-pounds-per-square-inch (psi). My hat is off to the engineering team at Darley on this diligent work! A team I appreciate standing behind our product, and a team you can count on to do the same for you.

For more information on the TSM 2000, to discuss Darley pump options with a member of our regional team, to schedule a tour, or for any other opportunities for Darley to serve, feel free to reach out to me at JasonDarley@Darley.com or on my cell phone at (715) 456-9390.

Jason S. Darley is North American sales manager for W.S. Darley & Company.