These units will be put into service immediately and then used as reserves once more customized fire apparatus are delivered.

Orange County (CA) Fire Authority Purchases 10 KME Severe Service Pumpers

These 10 pumpers will be a continuation of the significant design changes that Orange County has made to its fire apparatus since 2021.

KME Welcomes Fire Master Fire Equipment to Its Dealer Network

Fire Master Fire Equipment, Inc. is now an official dealer for KME® fire apparatus and equipment in Arkansas, Kansas, Missouri, and Oklahoma.

Vancouver (WA) FD Replaces Tractor Drawn Aerial With New KME Tiller

The department needed to replace the oldest of the tillers and wanted a new rig that mirrored the customization of its earlier TDAs.

REV Fire Group to Highlight Rigs, Celebrate E-ONE’s 50th Anniversary at FDIC

REV Fire Group (Booth 4200) will host REV It Up Coffee and Conversation with FDIC Live each morning, and REV It Up Happy Hour and live product walk-arounds on Thursday and Friday.

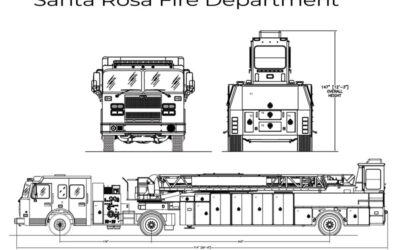

Santa Rosa (CA) FD Places Order for Two KME 101-Foot Tractor-Drawn AerialCats

The Santa Rosa Fire Department is set to receive two KME® 101-foot Tractor-Drawn AerialCats™ (TDA) to serve its area.

San Bernardino County (CA) FD Orders Four KME Custom 4×2 Pumpers and a 4×4 Pumper

These new vehicles will join the existing fleet of more than 50 KME units currently in service within the county.

KME Delivers 101-Foot Tractor-Drawn AerialCat to West Palm Beach (FL) FD

This marks the first TDA ordered for the city of West Palm Beach. West Palm also has ordered a 103-foot 4 Section Tandem Axle KME Tuff Truck™.

Walker Township (PA) Fire Company Gets Two Rescue-Pumpers Through Brindlee Mountain Fire Apparatus

The Walker Township (PA) Fire Company got two KME engines, a 2013 and 2010, from the Eddington (PA) Fire Company in a deal brokered by Brindlee Mountain Fire Apparatus. (Photos courtesy of the Walker Township Fire Company.)

Brindlee Delivery: 2006 KME Heavy Rescue

Brindlee Mountain Fire Apparatus recently delivered this KME heavy rescue to a southern fire department.

Clean Cab Concept and New Fire Apparatus

The fire apparatus industry is taking a proactive stance when it comes to firefighter cancer prevention by designing new apparatus that makes it easier for firefighters to decontaminate after a fire.

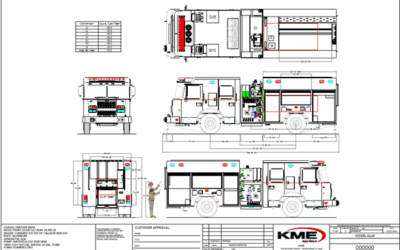

Pleasanton (TX) Fire Department Replaces Apparatus With KME Rear-Mount Pumper, Heavy Rescue

The Pleasanton (TX) Fire Department had KME build a rear-mount pumper and a heavy rescue with nearly identical physical profiles.