By Greg Moore

When I was a younger technician, just learning the trade, I heard the saying, “The biggest of issues can sometimes have the most obvious of solutions.” Although this certainly is not always the case, this saying has always stayed with me. Over the years, I have modified that saying slightly to read: “Sometimes the biggest of issues can offer you a diagnostic direction right before your eyes.” This has proven true to me so many times over my career. As emergency vehicle technicians, most of us are still blessed to have one of the most powerful diagnostic tools available to us—our eyes.

Here is a real life example, which happened to me last week. A fire apparatus was towed into our shop with some major drivability faults. Every warning light was on in the dash display, and the Allison controller was unresponsive. Although the Cummins engine would run, there was no throttle control, and it would only idle. The “Stop Engine” light was displayed constantly. This is one of those jobs where you can sometimes struggle to find the direction you need to start looking for the root cause of the main issue. Gaining that first diagnostic direction can sometimes be one of the hardest tasks in solving an issue. Having a solid understanding of how systems work, combined with basic diagnostic steps, such as the visual inspection, can sometimes offer you the help you need in securing a diagnostic direction. The apparatus that was currently in my bay is a perfect example of this.

The first step is always verify the issue. Collect all the information you can regarding the issue. Every single detail, no matter how small, is a valuable clue and should be treated as such. The second step in the diagnostic process is probably one of the most important ones, in my humble opinion: visual inspection. Treat the visual inspection with the same importance as gathering information about the problem. The visual inspection can uncover some small clues that lead to the main cause of a major issue.

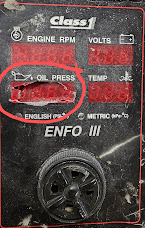

Broken screen on the Enfo III data display. (Photo 1)

After obtaining all the information I could from the crew regarding what exactly happened, I started my visual inspection. I always start at the outside of the apparatus, looking over every panel, instrument, and gauge. Although they should be thorough, visual inspections do not need to take large amounts of time. Upon my inspection, I saw a broken screen on the Enfo III data display (photo 1). This immediately caught my attention. From experience, I knew that the Enfo III is supplied by four wires: Power, Ground, Can Hi, and Can Low [1939 in the case of our apparatus] (photo 2). This device was directly connected to the high-speed communication networks of the apparatus. It was also located outside the truck on the pump panel, exposed to the elements, and now had a broken screen.

![From experience, I knew that the Enfo III is supplied by four wires: Power, Ground, Can Hi, and Can Low [1939 in the case of our apparatus]. (Photo 2)](https://www.rigspot.com/wp-content/uploads/2024/05/RIG050824_photo2.jpg)

From experience, I knew that the Enfo III is supplied by four wires: Power, Ground, Can Hi, and Can Low [1939 in the case of our apparatus]. (Photo 2)

I proceeded to remove the Enfo III from the pump panel and brought it to the bench. I opened the unit and indeed found evidence of water intrusion inside (photo 3). This was the device that caused the network to no longer transmit the critical data that was required for the apparatus systems to operate. The Enfo III unit was replaced, and the truck was able to return to service in a short period of time.

I proceeded to remove the Enfo III from the pump panel and brought it to the bench. I opened the unit and indeed found evidence of water intrusion inside. (Photo 3)

Many technicians experience anxiety when they have vehicles with a communication concern, and this is completely understandable. Today’s apparatus can consist of multiple complex high-speed networks and dozens of communication devices. Gaining diagnostic direction is often challenging. In this case, the visual inspection was a key part of helping me locate the root cause of this issue. Knowing and understanding how systems work is also a critical step in the diagnostic process, but sometimes the smallest clue can help you channel your knowledge and ability into the right area. This can also help prevent you from going down multiple rabbit holes when looking for the solution. Remember the basics and start with them. You will be amazed at how far that will get you sometimes.

GREG MOORE is the founder of F.A.T. Talk, a technical support group that helps fire apparatus technicians network, share knowledge and insight, and problem solve as a community. He is a mechanic with a 25 year long career, content creator, and father of two.