A fact is a verifiable truth; fiction is not. A politically correct way of dodging the truth is to call a statement a fallacy. A fallacy can be defined as a misconception, a myth, sometimes a mistake, even a fairytale and “perhaps it’s something you thought you heard.” In sales and marketing, a vendor’s dream is to make purchasers believe what the vendor wants them to believe—all the while knowing it may not be factual. It’s like pouring a glass of water on a customer’s shoes, telling him it’s raining, and the customer believing it. It can happen in the fire truck world.

Are Lightbars Really Required on Fire Apparatus?

The National Fire Protection Association’s NFPA 1901 Standard for Automotive Fire Apparatus sentence 3.8.13.2.1 says, “The upper-level optical warning devices shall be mounted as high and as close to the corner points of the apparatus as is practical to define the clearance lines of the apparatus.” The sentence is applicable to all corners of the apparatus, which is probably why they said devices—a plural indicating more than one light. It does not specifically call for a full-width, forward-facing lightbar on the cab roof. Nor does it specify multiple half-bars. Who says it has to be a lightbar?

The Standard calls for a minimum level of “optical power requirements” measured in candela-seconds/minute at certain distances and at established data points from the rig for both calling for the-right-of-way (responding) and blocking the right-of-way (stopped). The requirement states the output is measured “on the level” with lesser amounts required at specified distances both above and below the horizontal level. There is no qualm with those requirements.

The standard requires a 1 million “minimum optical power” output to satisfy the upper-level, forward-facing (Zone A) requirements when responding. It doesn’t say it has to be a continuous light from one side to the other. Several apparatus salesmen were asked whether a single warning light mounted on each corner of a cab roof satisfies that requirement. Most were not sure and suggested contacting the NFPA and the warning light manufacturers. Ask your local vendor to respond to the same question with a yes or no answer—you might have better luck.

Compliance by Insinuation?

Most light manufacturers’ published literature and websites only show lightbars of various sizes meeting the NFPA 1901 Zone A upper level requirements. By omission, are they indirectly stating only lightbars are compliant?

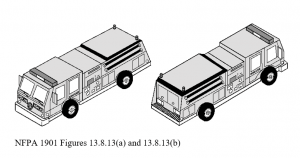

Even NFPA 1901’s Figures 13.8.3.2 and A.13.8.13(a) and A.13.8.13(b) illustrating the warning light zones depicts what appears to be a forward-facing lightbar. Is that a subtle hint that lightbars are preferred by the NFPA?

Real Life

Many gung-ho firefighters experience warm and fuzzy feelings when exposed to bright-flashing lights. Some believe in the “bigger and brighter is better” philosophy. Not all vendors have the same feelings, but many will—unfortunately—patronize a potential customer just to make a sale. “Sell them what they want—or whatever they can afford” is a questionable technique. Regardless of the reason, it just isn’t right—especially if the vendor is unaware of the facts. Don’t pour that glass of water on my shoes again and say it’s still raining.

A recent edition of a national fire apparatus photo journal showed about five dozen new structural rigs recently delivered or in service; all had mostly low-profile lightbars. The perception of warning lights today could be only low-profile lightbars are acceptable on the cabs of fire trucks.

Soon people might start believing only LED (light-emitting diode) warning lights are the only acceptable ones. I have nothing against LED lights, or strobes, or halogens, except for those that distract and cause discomfort to motorists rather than signal an understandable warning.

In my opinion, the sole purpose of roof-mounted warning lights is to inform distant motorists that there’s an emergency vehicle coming that wants the right-of-way or has already taken it. I believe the emphasis and expense should be on warning lights located below a rig’s windshield level where they are more in the line-of-sight of motorists and can perhaps entice them to take appropriate action. NFPA 1910’s Appendix A sentence A.13.8.1 somewhat concurs: “The upper-level optical warning devices provide warning at a distance from the apparatus, and the lower-level optical warning devices provide warning in close proximity to the apparatus.”

Asking vendors the minimum required warning lights on top of a fire truck is not being “anti-red light.” Vendors who say the most expensive lightbar in the Western Hemisphere “best meets the Standard” may be disingenuous. Salespeople want to sell their product—it’s their job. Don’t blame them for trying to put food on the table—as long as they keep the water glass upright and stop talking about it raining on your shoes.

In order not to disparage any lightbar manufacturer, fire apparatus vendor, or fire department, the below questions and answers are fictional. A couple of concerned taxpayers at an open house are looking over a department’s new delivery; a couple of firefighters answered their questions about the rig’s new lightbar.

*Is that one of them aerodynamic lights? “Yep, that’s what the salesman told us. He said they cost a little more but it’s well worth it.” How’s that? “They use the new super-bright LED lights that last longer than regular lights. They don’t burn out as quick and don’t need to be replaced as often as older lights. It saves us money.”

*Is that what aerodynamic means? “No, no—aerodynamic means it’s much lower than older-style lightbars. There’s less resistance.” Resistance to what? “The wind of course. They’re called low-profile bars because they’re aerodynamically designed to create less drag—like airplanes are built.”

“You guys really like the low-profile design? “We sure do. It keeps our fuel costs down and fuel’s expensive. We’re going to retrofit our ladder truck with smaller versions of the same bar on each side of the cab. And I’m sure you noticed that all the police cars in town now use the low-profile design. It saves money.”

*When I was a kid, the older trucks had a single gumball light on top that spun around. And I think the newer ones had two gumballs on the roof. You can’t use them anymore? “They’re not as bright and functional as the new LED lightbars. We’re regulated by the National Fire Protection Association and have to meet certain brightness requirements on all four sides of a fire truck. The intent, you know, is to protect motorists and prevent accidents. We did a lot of research. The salesman said the lightbar we chose is the best one to protect motorists.” (Of course he said that.)

***

Did those firefighters actually believe what they were saying or were they regurgitating what a salesman told them or led them to believe? They didn’t mention when the salesman was at their purchasing committee meeting using a laptop to “build” a rig on paper—it initially showed an inexpensive but compliant lightbar. The vendor recommended upgrading to the biggest and best on the market. (Bait and switch?)

The firefighters were not forthright about the NFPA. It does not require a full-length lightbar on the cab roof. Perhaps the vendors did not tell the firefighters, or the manufacturers did not tell the vendors. (Plausible deniability?)

Less wind resistance? Behind the two-inch, high low-profile lightbar on the lower cab roof sits a nested light tower. And behind that is a 15-inch raised roof on the crew cab. As far as retrofitting their aerial device, does a couple two-foot-long, two-inch-high lightbars create more wind resistance and drag than the actual aerial device sitting on top of the cab roof? (Common sense?)

Lightbar Disclaimer

I have nothing against lightbars or the people who like them. I am not advocating going back to the days of a combination siren and flashing red light on the roof (photo 1) or a single 1930’s era Mars figure 8 light (photo 2); both are ineffective on their own. I don’t think a single beacon ray will meet the standard (photo 3). And, dual beacon rays (photo 4) or similar lights may have merit in showing a rig’s size, but it’s unknown if they’ll meet the standard. It is acknowledged that a lightbar can be an excellent platform for mounting work lights, scene lights, and traffic control devices.

Photo 1

Photo 2

Photo 3

Photo 4

I asked Ken Menke of PowerArc about the history of lightbars. He provided the following info from various manufacturers’ websites. “The godfather of the lightbar is Earl Gosswiller, with Federal Signal. He invented the TwinSoinc, the first lightbar. His ideas were put into motion (see patent numbers 3,404,371 and 3,271,735 and 3,281,030) in 1967 for a fully enclosed rotating beacon light that stretched across the roof of patrol cars. The Twinsonic debuted at the 1968 International Association Fire Chiefs convention in Louisville Ky. The lightbar was as instant success.”

“Code 3’s first lightbar, the 2200 (1974-1976), was a copy of the shell of the Twinsonic with different internals. Federal had not applied for a design patent. They did shortly after and going forward on all future bars.”

“Whelen introduced the 6000 series bar which placed strobes and flashers under a common dome in 1975 followed by the 8000 in 1978 and the Edge in 1983.

***

Menke said, “By the mid-to-late ‘70s and early ‘80s most fire engines had moved to the full lightbar.” I wonder why? Are fire apparatus really required to have full-length lightbars? Is there another more effective light? Do light manufacturers have a product other than a lightbar that meets NFPA 1901 “minimum optical power” requirements for Zone A upper coverage? Just wondering.